Traditionally, iron, aluminum, and aluminum vapor- deposited plastics are the materials used to build the backside cases of plasma displays.

For these materials, the following measures are taken:

• The holes on the case are blocked with conductive sheets.

• The case is installed with the presence of mediated conductive gaskets, preventing the case from electronic isolation and thus function as an antenna.

Recently, however, a serious problem has been recognized with this system: the inside of the case functions as a resonator, and therefore unnecessarily amplifies radio waves by as much as 100 or 500 times.

This is often caused by leaks in the holes of the case, the cables, or the screen.

For this reason, a conductive case with radio wave absorbing function --- the case is conductor and its surface has property of radio wave absorption, so that it becomes conductive when connected --- has become more important than ever.

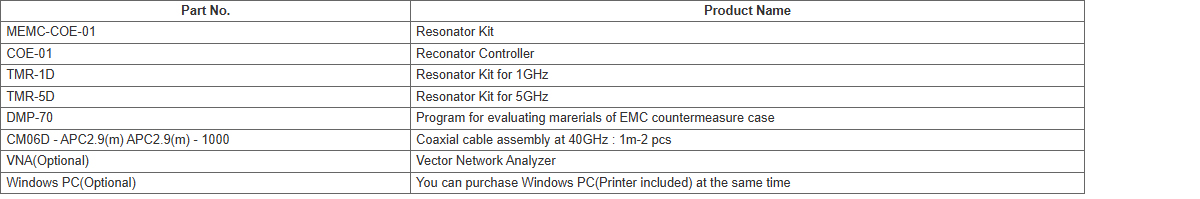

KEYCOM's compact measurement system is of great help to develop materials having this characteristics.

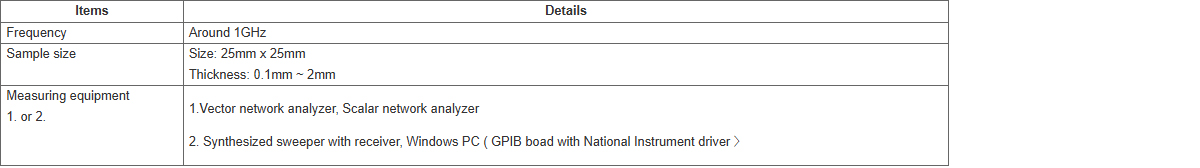

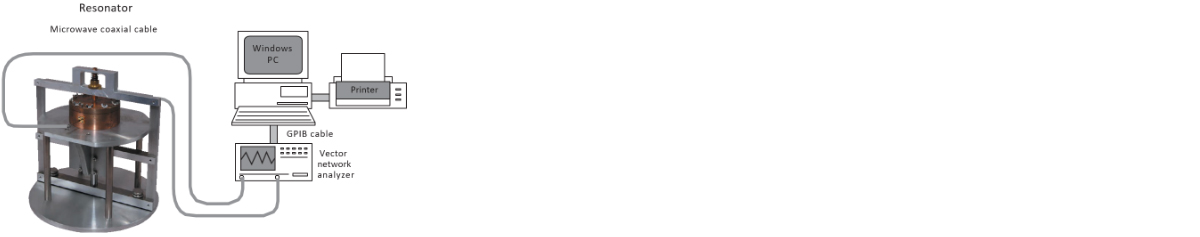

Cut the material into a square with 25 mm sides, attach the square to a plastic fixture, and place the square into a resonant cavity (see picture on the left).

The resonance frequency and the Q value of the empty resonator grow lower when the sample specimen is inserted.

The lower the Q value drops, the better the material of the case.

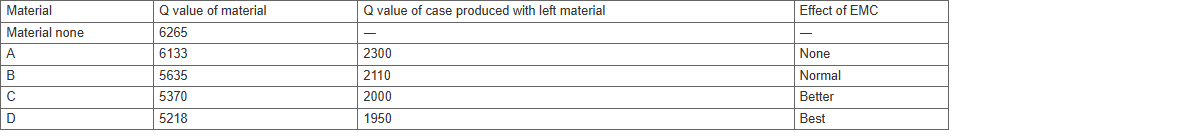

The Q value of the material measured with this system, as well as that of the case fabricated with the material measured, are shown in Table 1, where the trend corresponds well with the EMC effect.

Table 1. Q value by this system of various materials and Q value of case

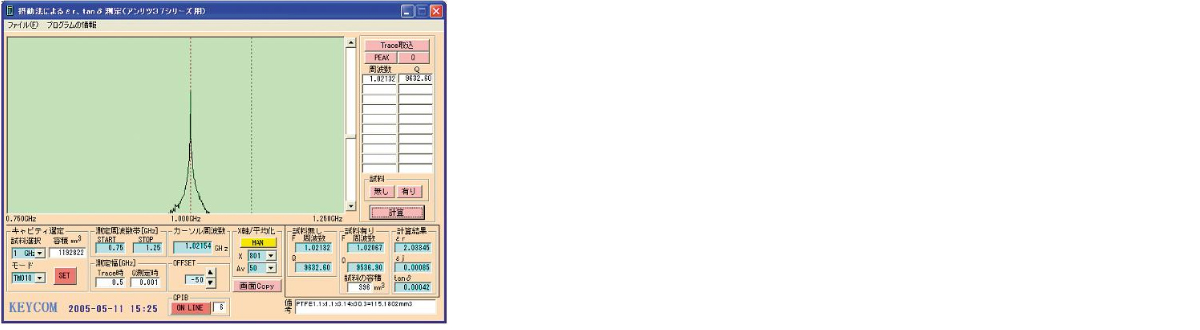

One example of the measurement screen when material C is measured is shown as below image.

It is a resonance curve. Q value is indicated in a right part.

Measurement Example